- Dahisar(W.), Mumbai, Maharashtra

- GST NO. : 27AATCS3987J1ZC

- +91-9821615038

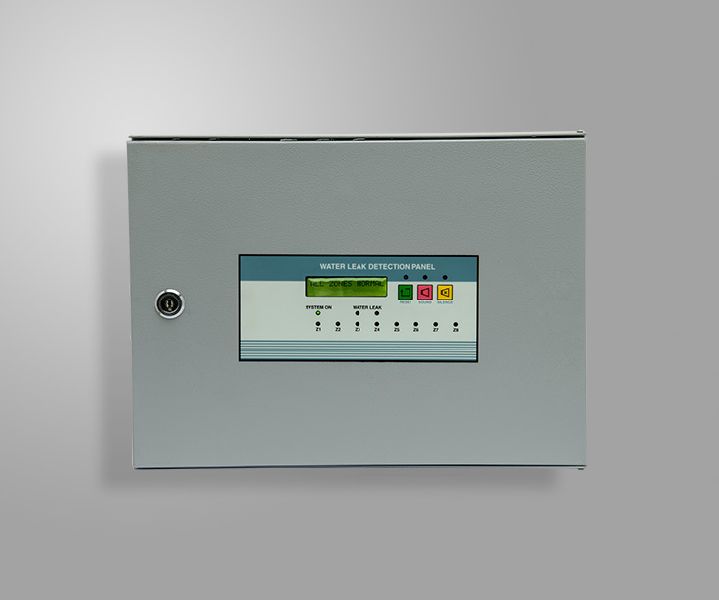

Conventional Panel

Leading Manufacturers, Exporters, Wholesaler and Retailer of Water Leak Detection Conventional Panel ... JAY 3523, Water Leak Detection Module Je 1141 and Water Leak Detection Touch Screen Conventional Panel Sy T103 from Mumbai.

| Business Type | Manufacturer, Supplier, Retailer |

| Tender Specification | |

| Supply Voltage | 230V AC – 50Hz +/- 10 % |

| LCD Display | Backlit. |

| Relay | Zone Relay’s and one common Relay. |

| SPDT single contact | NO-NC. |

| Internal Sounder | Buzzer to indicate Leak. |

| External Sounder | Hooter 24VDC. |

| Current consumption standby | 0.4Amp. |

| Response Time | < 3 Sec. |

| Alarm State | 0.8 Amp. |

| Working Temp. | 10 to 50Degree C. |

| Construction | Metal Enclosure Wall mounted. |

| Weight | 3 Kgs Aprrox. |

| Size ( HXWXD) : 270x360x115 | 270x360x115 mm |

Preferred Buyer From

| Location | Anywhere in India |

The water leak system comprises of a Main zone water leak panel, interface modules, sensor cable and alarm sounders. The water leak panel has potential free relay contacts which extends alarms to BMS.

The Water leak detection sensor cable typically used to detect water leaks in critical rooms to monitor leakage and optionally extend alarm in the BMS. The Cable draws excitation signal from a start of the line module. It serves as an interface between the Water leak detection panel and the Sensor Cable. The Start of Line Interface Module is locally placed in the False Flooring, and shall be connected to the WLD Panel through standard Cu- Ar Cable.

The WLD Panel is be capable of supplying power to the interface modules, and serves as the annunciation of alarms through LCD fascia. The panel activates common sounder. Testing procedure involves physical application of a wet cloth to the cable, to test the relay operation. The Panel sounds the Alarms, and optionally notifies the BMS system.

Features of Products :

- The panel equipped with LCD Display can monitor 20 Zones.

- Input to water leak cable is an isolated Ac supply which ensures the cable will not be subject to oxidation and erosion over time avoiding the degradations problems associated with DC system.

- The panel is equipped with SPDT keypad for navigation.

- Compact and elegant looks.

| Business Type | Manufacturer, Supplier, Retailer |

| Supply Voltage | 230V AC – 50Hz +/- 10 % |

| Output to WLD Cable | Isolated A.C. Supply 12V. |

| SPDT single contact | NO-NC. |

| Current consumption standby | 0.4Amp. |

| Response Time | < 3 Sec. |

| Alarm State | 0.8 Amp. |

| Working Temp. | -10 to 50Degree C. |

| Size HXWXD | 120X200X75mm |

| Weight | 1kg (approx.) |

| Size ( HXWXD) | 120x200x75 mm |

| Construction | Metal Enclosure Wall mounted |

Preferred Buyer From

| Location | Anywhere in India |

The water leak system comprises of a Main zone water leak panel, interface modules, sensor cable and alarm sounders. The water leak panel has potential free relay contacts which extends alarms to BMS.

The Water leak detection sensor cable typically used to detect water leaks in critical rooms to monitor leakage and optionally extend alarm in the BMS. The Cable draws excitation signal from a start of the line module. It serves as an interface between the Water leak detection panel and the Sensor Cable. The Start of Line Interface Module is locally placed in the False Flooring, and shall be connected to the WLD Panel through standard Cu- Ar Cable.

Testing procedure involves physical application of a wet cloth to the cable, to test the relay operation. The Panel sounds the Alarms, and optionally notifies the BMS system.

Features of Products :

- Given an isolated supply AC supply to water leak cable to avoid oxidation or erosion of cables over a period of time.

- The module can be connected to water leak Detection Annunciation Panel.

- The module provides potential free relay output.

- The module comes in ABS enclosure.

- The module has compact and elegant looks.

| Business Type | Manufacturer, Supplier, Retailer |

| Supply Voltage | 230V AC – 50Hz +/- 10 % |

| Display | Touch Screen, 3.2TFT |

| SPDT single contact | NO-NC |

| Internal sounder | Buzzer to indicate Leak and fault |

| External Sounder | Hooter 24V DC. |

| Fuse | 1Amp. |

| Response Time | < 2 Sec |

| Alarm State | 0.8 Amp |

| Working Temp. | 10 to 50Degree C |

| Construction | Metal Enclosure Wall |

| Weight | 4.5 Kgs Aprrox |

| Size ( HXWXD) | 270x360x115 mm |

Preferred Buyer From

| Location | Anywhere in India |

The water leak system comprises of a touch screen water leak panel, sensor cable and alarm sounders. The water leak panel has potential free relay contacts which extends alarms to BMS.

The Water leak detection sensor cable typically used to detect water leaks in critical rooms to monitor leakage and optionally extend alarm in the BMS. The WLD panel is enabled with a touch screen display, which makes the use of switches redundant.

Testing procedure involves physical application of a wet cloth to the cable, to test the relay operation. The Panel sounds the Alarms, and optionally notifies the BMS system.

Salient Features :

- The panel equipped with Touch Screen Display can monitor up to 8 Zones:

- Zone sensitivity feature is provided which enables the user to set the sensitivity of sensing cables as per the site requirements.

- Zone addressing facility is provided in the settings which enables the user to name the zones as per the site specifications.

- Zones can be isolated at Power on/Reset.

- Event log of 100 events is provided.

- Input to water leak cable is an isolated Ac supply which ensures the cable will not be subject to oxidation and erosion over time avoiding the degradations problems associated with DC system.

- Zone wise potential free relay output is provided for BMS.

- Compact and elegant looks.

- Panel is equipped with cable break condition where zone window turns blue in case if the cable is disconnected or if it breaks.

- Cable break condition is implemented in the system which will give an alarm for the zone whose cable has been damaged or removed. The respective zone window will turn blue.